Thank you both for your replies. I tried changing the file extension under preferences to GCD and loading the cam files into Prototrak as GCD files. Both ways didn't work. By eliminating arc moves, I was able to get some cam files to loade as GCD files and run but not all. For small files, I load the cam files as F6M and they are automatically converted to PT4 files.

This works well for conturing but the large cam files generated for surfacing, freeze the SM controler and I have to re boot. I've never used PostHaste and the fellow teaching me Gibbs hasn't either. There is some hope that the Gibbs reseller can find the GCD post developed for Prototrak but if he can't, I may have to try it. I was also told by Prototrak that the G-code for the cam and gcd files is very similar and that editing the G-code generated by my Gibbs post processor might offer another option. I loaded the PostHaste and found four Prototrak Post processors.

Two were for 3 axis. Unfortunately they both produced cam files which is what my post processor already produces. Still hopefull that the Gibbs reseller can find the Gibbs Prototrak GCD post processor. How do you run your really large files? Is there another way besides using the GCD files? The SM controller can handle.mx2.mx3, PT4,dxf,cam and gcd files. My post processor produces cam files which load as 6FM files and are converted to PT4 automatically.

But files over about 37,000 freeze up the SM controller and I have to re boot. Prototrak recommended using the gcd files. Most of the time, I can get away with loading the cam files as GCD files (as long as I eliminate the arcs which the gcd files can't handle) but am looking for a post processor that produces native GCD files or some other way of running large files. The SM controller can handle.mx2.mx3, PT4,dxf,cam and gcd files. My post processor produces cam files which load as 6FM files and are converted to PT4 automatically. But files over about 37,000 freeze up the SM controller and I have to re boot. Prototrak recommended using the gcd files.

Most of the time, I can get away with loading the cam files as GCD files (as long as I eliminate the arcs which the gcd files can't handle) but am looking for a post processor that produces native GCD files or some other way of running large files. OttoOkay, so a plain old Fanuc 6 post processor won't jive anymore? They always touted that a modified Fanuc 6 was a good enough post processor. I have the older VM control and.cam extension file with the ProtoTRAK translator never had an issue (and was files with +20,000 lines.large engravings). After you have your toolpath in Gibbs, look on the top menu bar. Highlight 'Plug-Ins'. Then 'Postings', Then 'Poste-Haste'.

Hit the 'browse' where it says 'Template to post with'. It should give you a pop-up menu with about 200 machine controls on it. ProtoTrak has 3 different templates shown. Start at the top and work your way down until you get the output you want. You can take that template and tweek it.

Post Library for Fusion 360 and Autodesk HSM. This is the place to find post processors for common CNC machines and controls. Make sure to. MasterCam Post Processor postprocessor CAM post-processor PostHaste Creo CamWorks Pro/E CATIA NX Pro/ToolMaker TekSoft Unigraphics. In addition to developing post processors for the Mori Seiki NMV line, Gibbs has also developed accurate machine models of the NMV8000 DCG and NMV5000 DCG for use.

Thats what I did for my home mill. Have fun irmachinistThat's interesting, irmachinist, Never tread in there before. Should play with it. We use a post file from the reseller for posting to the work machine.

I need a different machine to play with, I suppose.

Page/Link: Page URL: HTML link: The Free Library. Retrieved Feb 09 2018 from.

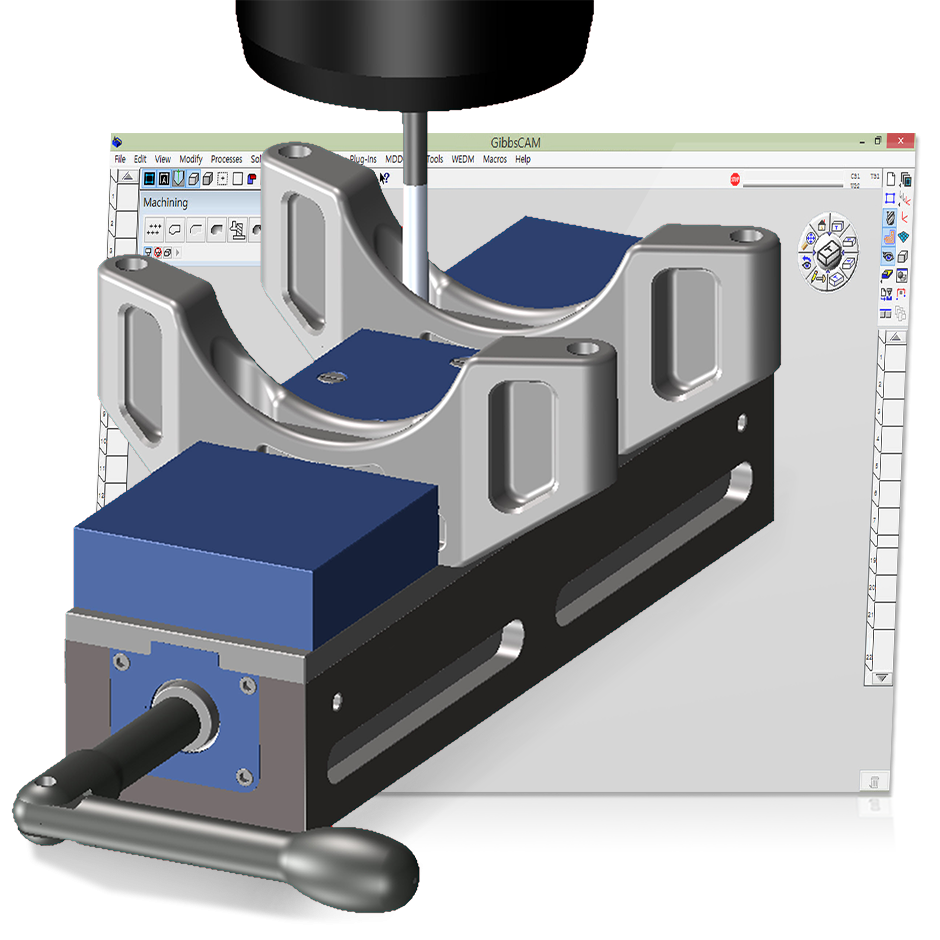

Collaboration Between The Two Companies Ensures That GibbsCAM Supports 5-Axis Programming MOORPARK, California, May 27 /PRNewswire-FirstCall/ - Cimatron Limited, a leading provider of integrated CAD/CAM solutions for the toolmaking and manufacturing industries, announced today that the set of its GibbsCAM(R) product's post processors that was developed for Mori Seiki's NMV line of machine tools has been validated by Mori Seiki. This collaborative effort between the two companies ensures that GibbsCAM's posted output supports the 5-axis simultaneous capabilities of these machine tools. As competitive pressures grow, the market demand for 5-axis simultaneous machine tools is also growing as they significantly reduce setups and improve overall part quality. 'Accurate post processors are still the Achilles tendons of today's advanced machine tools,' explains Bill Gibbs, founder and CEO of Gibbs and Associates. 'This is certainly the case when dealing with 5-axis machine tools. Working directly with Mori Seiki DTL, we were able to significantly reduce the time it took to develop the set of post processors for their NMV series.' The Mori Seiki NMV series of machine tools are high-precision, 5-axis control vertical machining centers.

Using Mori Seiki's DCG(R) (Driven at the Center of Gravity) technology, vibration is controlled allowing for high precision at high speeds. DCG virtually eliminates vibration ensuring a high quality surface finish, outstanding acceleration performance and improved roundness.

DCG along with Mori Seiki's DDM(TM) (Direct Drive Motor), Table-in-Table Construction and ORC(TM) (Octagonal Ram Construction) provide the NMV series with the power and stability required for today's demanding machining applications. In addition to developing post processors for the Mori Seiki NMV line, Gibbs has also developed accurate machine models of the NMV8000 DCG and NMV5000 DCG for use with GibbsCAM's Machine Simulation capability. Machine Simulation allows program motions to be fully simulated to identify potential programming errors which would result in expensive machine tool crashes on the shop floor. For more information about GibbsCAM or to locate your local GibbsCAM Reseller, go to call +1-800-654-9399, or email info@GibbsCAM.com. For more information about Mori Seiki and their line of machine tools, visit About Gibbs and Associates and GibbsCAM For over twenty years, Gibbs and Associates has been a leader in providing cutting edge CAD/CAM technology, while maintaining its signature ease-of-use and productivity. Powerfully Simple, Simply Powerful is the guiding philosophy at Gibbs. Gibbs believes in empowering the NC programmer, machinist, and manufacturing engineer, not eliminating them.

Gibbs' goal is to introduce manufacturers to new technologies and new ways of working that makes their machining easier and their businesses more profitable. To achieve this goal, Gibbs creates tools that are naturally intuitive, graphically interactive, extremely visual, associative, and just plain enjoyable to use. Gibbs provides a total quality solution with the service and support successful customers require.

The current GibbsCAM product line supports 2- through 5-axis milling, turning, mill/turning, multi-task simultaneous machining and wire-EDM. GibbsCAM also provides fully integrated manufacturing modeling capabilities that include 2D, 2.5D, 3D wireframe, surface, and solid modeling. GibbsCAM has received Microsoft's 'Designed for Windows XP/2000' and 'Works with Windows Vista' certifications. GibbsCAM's data exchange capabilities are able to access the broadest range of native and industry standard CAD data formats. GibbsCAM is certified under the Autodesk Inventor Certified Application Program, is a Solid Edge Certified Select Product, and is a SolidWorks Certified CAM Product. GibbsCAM is either offered or endorsed by a number of leading worldwide control and machine tool manufacturers, including GE Fanuc, Infimatic, Siemens, Doosan Infracore, Haas, Index, MAG Fadal, Mazak, Mitsubishi, Mori Seiki, and Tornos. Gibbs and Associates distributes its products worldwide through a network of international Resellers.

Gibbscam Post Processors For Haas Lathes

In January 2008, Gibbs and Associates merged with Cimatron Ltd, and is now operating as a wholly owned subsidiary. For more information about Gibbs and Associates and its CAM software packages, call 1-800-654-9399, or visit the company on-line at About Cimatron With over 25 years of experience and more than 40,000 installations worldwide, Cimatron is a leading provider of integrated, CAD/CAM solutions for mold, tool and die makers as well as manufacturers of discrete parts. Cimatron is committed to providing comprehensive, cost-effective solutions that streamline manufacturing cycles, enable collaboration with outside vendors, and ultimately shorten product delivery time. The Cimatron product line includes the CimatronE and GibbsCAM brands with solutions for mold design, die design, electrodes design, 2.5 to 5 axes milling, wire EDM, turn, Mill-turn, rotary milling, multi-task machining, and tombstone machining. Cimatron's subsidiaries and extensive distribution network serve and support customers in the automotive, aerospace, medical, consumer plastics, electronics, and other industries in over 40 countries worldwide. Cimatron is publicly traded on the NASDAQ exchange under the symbol CIMT.

For more information, please visit the company web site at: The Gibbs logo, GibbsCAM, GibbsCAM logo, Virtual Gibbs, Gibbs SFP, SolidSurfacer, MTM and 'Powerfully Simple. Simply Powerful.'

Gibbscam Post Processors

Are either trademark(s) or registered trademark(s) of Gibbs and Associates in the United States and/or other countries. Microsoft, Windows, and the Windows logo are trademarks, or registered trademarks of Microsoft Corporation in the United States and/or other countries.

All other brand or product names are trademarks or registered trademarks of their respective owners. Safe Harbor Statement This press release includes forward looking statements, within the meaning of the Private Securities Litigation Reform Act Of 1995, which are subject to risk and uncertainties that could cause actual results to differ materially from those anticipated.

Such statements may relate to the company's plans, objectives and expected financial and operating results. The words 'may,' 'could,' 'would,' 'will,' 'believe,' 'anticipate,' 'estimate,' 'expect,' 'intend,' 'plan,' and similar expressions or variations thereof are intended to identify forward-looking statements. Investors are cautioned that any such forward-looking statements are not guarantees of the future performance and involve risks and uncertainties, many of which are beyond the company's ability to control. The risks and uncertainties that may affect forward looking statements include, but are not limited to: currency fluctuations, global economic and political conditions, marketing demand for Gibbs and Associates or Cimatron products and services, long sales cycle, new product development, assimilating future acquisitions, maintaining relationships with customers and partners, and increased competition. For more details about the risks and uncertainties of the business, refer to the Cimatron's filings with the Securities and Exchanges Commission. The company cannot assess the impact of or the extent to which any single factor or risk, or combination of them, may cause.

Gibbs and Associates and Cimatron undertake no obligation to publicly update or revise any forward looking statements, whether as a result of new information, future events or otherwise. EDITOR'S NOTE: Electronic image and caption available upon request. For More Information Contact: Yvonne Anderson Gibbs and Associates Phone:+1(805)523-0004 Fax: +1(805)523-0006 Email: Yvonne.Anderson@GibbsCAM.com Ilan Erez Chief Financial Officer Cimatron Ltd. Phone: +972-3-531-2121 Email: ilane@cimatron.com Yael Nevat Commitment-IR.com Phone: +972-3-611-4466 +972-50-762-6215 Email: yael@commitment-IR.com CONTACT: For More Information Contact: Yvonne Anderson, Gibbs and Associates, Phone:+1(805)523-0004, Fax: +1(805)523-0006, Email: Yvonne.Anderson@GibbsCAM.com; Ilan Erez, Chief Financial Officer, Cimatron Ltd., Phone: +972-3-531-2121, Email: ilane@cimatron.com; Yael Nevat, Commitment-IR.com, Phone: +972-3-611-4466, +972-50-762-6215, Email: yael@commitment-IR.com.